Mill Plant

Ash Handling Plant

Boiler

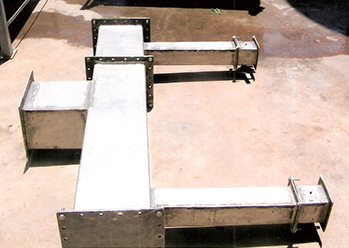

Material Handling Plant

Cooling Water Pump

Turbine

Engineering Project

MILL PLANT SPARES

ASH HANDLING PLANT

All spares to ash slurry pumps such as impellers, casings, sleeves, shafts, wear plates & sleeves

BOILER SPARES

MATERIAL HANDLING PLANT

Services

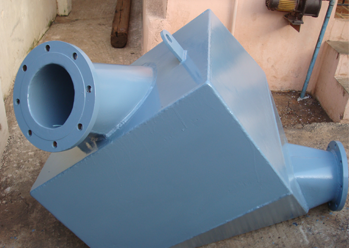

COOLING WATER PUMP

Services

of pumps

Blowers

TURBINE SPARES

ENGINEERING PROJECT

Duty Point Head 7 M - Flow 470 m3/hr (20 HP